S3 double axis servo drive

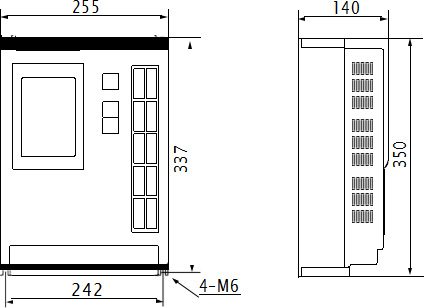

◆ Shape and mounting size

◆ Standard specification

Power:Three Phase 50/60Hz 380/400/440V

| Model | Main drive unit (S axis) |

Auxiliary drive unit (X axis) |

Brake resistance (Model X quantity) |

|||

| Rated power(kW) | Rated current(A) | Rated power(kW) | Rated current(A) | axis quantity | ||

| MAS-S3-45P5-4XXX | 5.5 | 13 | 1.5/2.2/3.7 1P5/2P2/3P7 |

4/5/8 | 3 | B800W40R×1 |

| MAS-S3-47P5-4XXX | 7.5 | 17 | 3 | B1000W32R×1 | ||

| MAS-S3-4011-4XXX | 11 | 25 | 3 | B600W50R×2 | ||

Note: The power of X axis,Y axis and Z axis, user can choose according to application requirements.

◆ Performance index:

● Main drive unit:S axis,5.5~11KW

● Main drive unit:S axis,5.5~11KW

● Auxiliary drive unit:three axis(X/Y/Z),1.5~3.7KW

● Drive motor:AC induction servo motor/PMSM

● S axis function: forward/reversal rotation,accurate stop,rigid tapping, C-axis

● X/Y/Z axis function:speed control,positioning control,zero return

● Communication interface: RS232 RS485 Ether net

● Bus Interface:MECHATROLINK ETHER CAT PROFINET

● The axial-control signal, impulse output, I/O, encoder output

● Relay output:3 channels(S/X/Z axis drive failure)

● The hand wheel/external encoder interface: 1 channel incremental pulse input

● The motor encoder interface:3 channel CTB BUS

● Optional configuration: touch screen, the hand wheel, external encoder

● Control function: independent control of each axis, multi-axis joint control

● Suitable CNC control system: Syntec, Siemens 808, domestic system

● Applying area: CNC milling machine, machining center, high speed drilling machine, engraving and milling machine, router etc

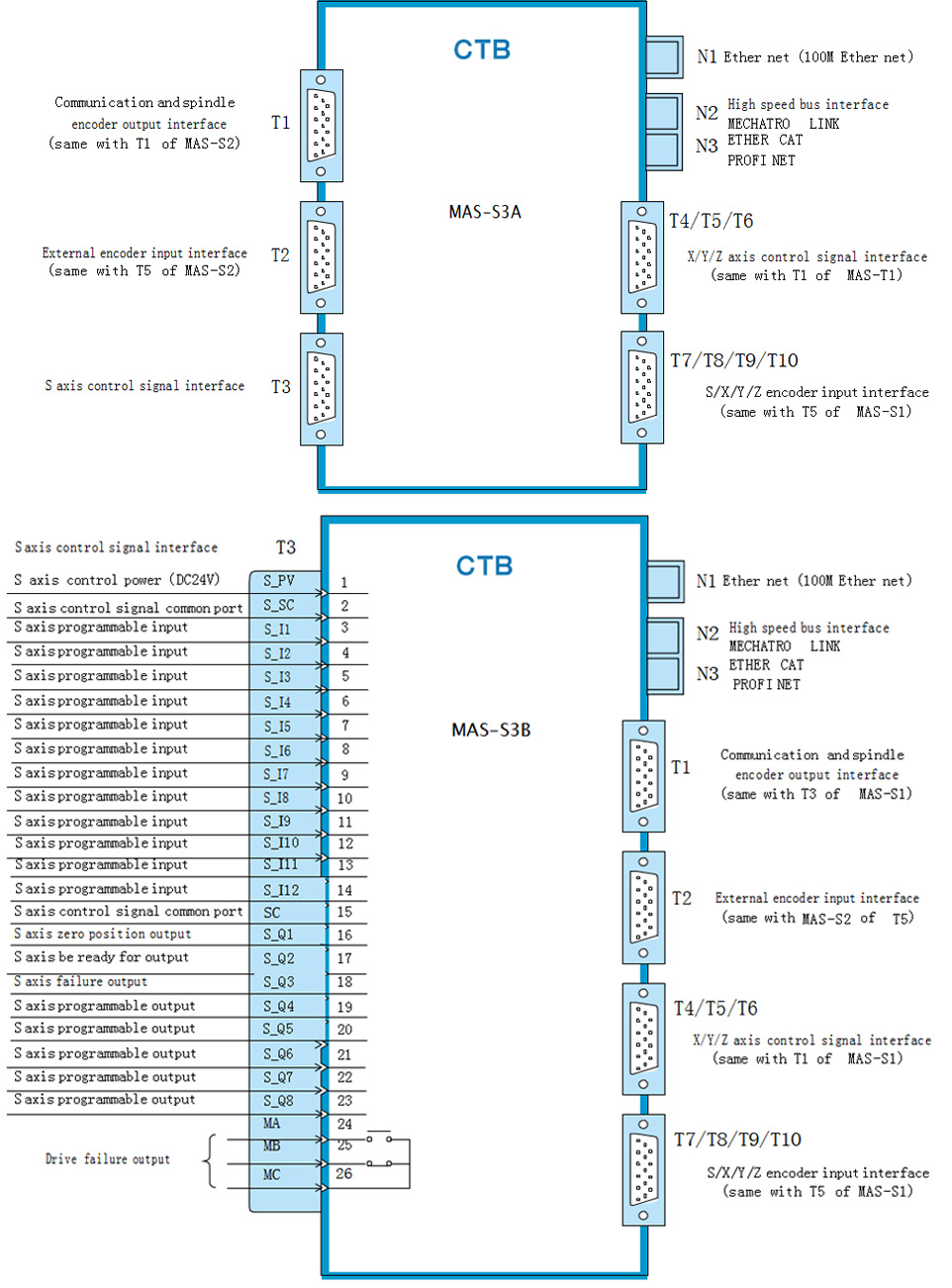

◆ MAS-S3 standard wiring diagram