With the development of petroleum industry, humans have a rapid demand growth of oil. Pumping unit as the key part of oil field production equipment, has been widely valued and developed, especially to improve the pumping performance, effect of energy saving is of great significance. In recent years, the emerging of motor and control technology, power electronics technology widely used in the pumping unit, the pumping unit and its control got rapid development.

Control system of pumping unit developed by Beijing CTB servo co., ltd has a perfect performance, energy efficient, simple operation and high degree of automation, which is optimal configuration of oil pumping unit control system.

CTB launched special servo control system solution for pumping unit, in recent years, we relying on our own patents, being unique in technical innovation of oil field production equipment, has developed a series of fully functional oilfield product, which is the first selection of intelligent and digital oilfield products.

Functional characteristics

1. Drive Built-in Pmotion motion control module, can use ladder diagram or C language programming;

2. DSP + FPGA double CPU design for drive, a variety of control algorithm

3. Professional graphic analysis software, powerful operation ability;

4. Intelligent parameter collection, real-time monitoring;

5. Realize full closed-loop control, position control, speed control and torque control;

6. Control precision:position:±1PLUSE、speed:±0.1%、torque:±5%

7. Quick response of servo control;

8. 200% of overload ability, faster and more efficient response

9. Energy saving, high efficiency of servo control , saving production cost

10.Power-lose protection and fault emergency braking function.

Servo control characteristics of pumping unit

1. Core of servo control: Pumping rate stepless automatic adjustment

a. Solve the problem of deficient-liquid supply, need interval pumping.

b. Solve pumping rate problem by changing mechanical variable transmission ratio

c. Fundamentally solved problems of saving energy, increasing production, improving efficiency.

2. Servo control:Stroke automatic stepless adjustment

a. Improve down stroke velocity, transfer up-stroke energy into down stroke power effectively, save a lot of power;

b. Reduce stroke speed, reduce output power of up-stroke motor, improve depth ratio of pump.

3. Servo control, energy-saving features

a. Fully meet feed fluid situation of down hole by adjusting pumping rate, make full use of electrical energy;

b. Improve power factor, reduce reactive power loss of power grid;

c. Adjust output voltage and torque timely according to load condition of pumping unit, in order to meet the needs of the pumping unit and optimization of energy utilization.

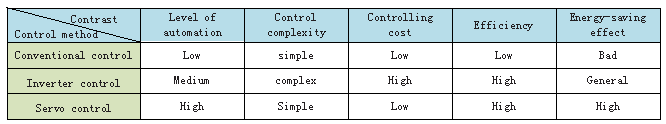

Pumping unit control scheme comparison

Market orientation

1. The CTB products are suitable for all kinds of high-end industry

a. beam-pumping unit

b. Derrick framed pumping unit

c. Electric submersible progressing cavity pump

d. Electric submersible centrifugal pump

2. High cost performance, obvious price advantage in servo market

3. Energy saving and efficient, cost savings for production enterprise

4. With different communication interface, can communication with all kinds of touch screen, text box