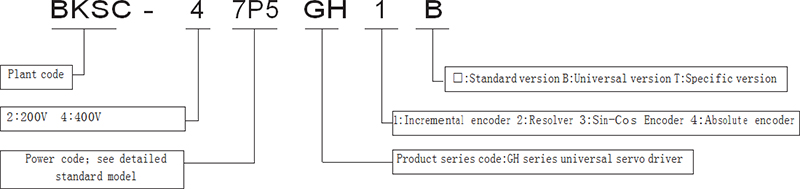

◆ Demonstration of driver (7.5kw for example)

◆ Software function

| Function name | Usage | Purpose | Function demonstration |

| Arbitrary point positioning | Mechanical transmission | Automatic process control | Servo motor starts running to the setting position , localization stopped and sent position signal when received run command |

| Reciprocating positioning operation | Mechanical transmission | Automatic process control | Reciprocating motion between two setting positions, can set speed of movement; Typical application: double housing planer |

| Multi-point positioning | Mechanical transmission | synchronous process control | Can set up 256, corresponding to the input signal is valid, the motor running to the corresponding position |

| Impulsive synchronization | Mechanical transmission | Synchronous control | Operation of Servo motor is synchronous with the input pulse,synchronization ratio can be set, often used for NC machine tool and numerical control equipments. |

| Synchro-driven | Mechanical transmission | synchronous running | Two(more than two sets)servo motor achieve synchronization |

| Torque control | Press machine | Output torque adjustment | Use analog input signal or communications real-timely to adjust the motor output torque, meet the needs of the load |

| parallel drive | Roller way, drive machine | Achieve equilibrium output | Multi-driver via bus communication, drive same load together, ensure each motor with same output. |

| Constant length cut | transverse cutting machine wire cutting | Automatic synchronization fixed- length cutting | Driver test the length of cutting object via outer encoder, automatically calculates starting position, synchronously cutting when reaching cutting length. |

| PLC programming | General machine | logic control | Can provide at most 12 points input,8 points output programming control function, users can program freely as per mechanical control needs |

| Independent arithmetic | Rotary cutting machine and other equipment | Automatic calculation of running speed | Driver automatically calculates feed speed of tool frame to achieve constant linear speed rotary cutting as per the speed of main drive roller and tool frame position. |

| Input/output condition monitoring | General machine | Monitoring interface condition | Monitor all input/output signal of driver via U2 parameters, make convenience for debugging and troubleshooting |

| Connect touch screen | General machine | Provide the man- machine interface | Can connect the standard touch screen to driver via serial interface, operate driver, achieve running, parameter adjustment, condition monitoring etc. function |

| Hydraulic servo drive | Hydraulic equipment | Automatic pressure control and energy saving | Test fluid pressure via pressure sensor, achieve constant pressure control via PID adjustment. |

| Bus communication | Production line | remote automatic control | Driver connected to internet via MODBUS, CAN, POWERLINK etc. Bus to achieve centralized control |

| Remote operator | General machine | The simple remote monitoring | Achieve driver remote operation via connecting with remote digital operator, revise parameters, monitor Important operating data |

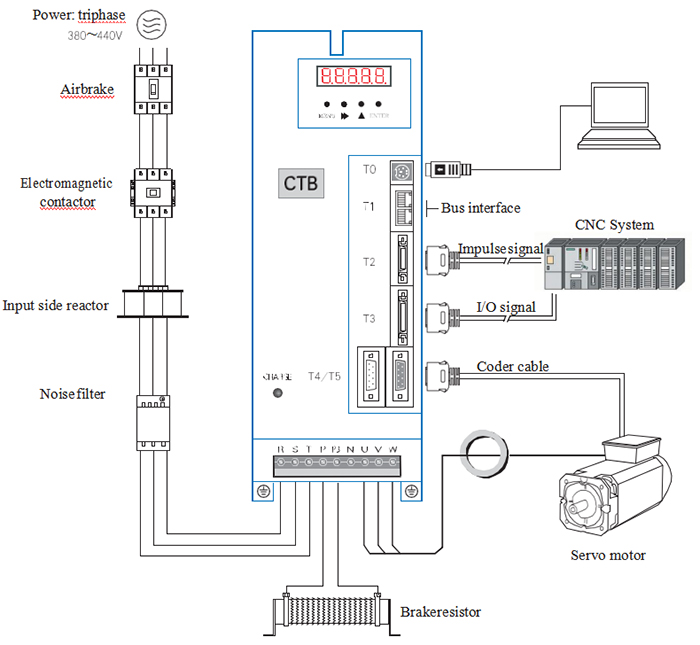

◆ System connection schematic (7.5kw for example)

◆ Instruction of components type selection

| Name | Application | Considerations in type selection | Remarks |

| Airbreak | Connect on or out off driver power | Type selection according to the 150% of rated current of driver | Refer to GH Common used accessories selection(PO9) |

| Electromagnetic contactor | Used to automatic power for driver or automatically cut off power supply if failure. | Type selection according to the 150% of rated current of driver | |

| AC reactor | To improve the power factor of power grid, restrain power higher harmonic | Type selection according to the 100% of rated current of driver | |

| Noise filter | Prohibit the interference of power from driver | Type selection according to the 150% of rated current of driver | |

| Braking resistor | Consuming the recovered energy of driver | Type selection according to the manufacture’s standard | Refer to GH Common used accessories selection(PO9) |

| Filter magnetic ring | Prohibit the external radio frequency interference and common mode interference | Type selection according to the manufacture’s standard | Refer to GH Common used accessories selection(PO9) |

◆ Control circuit terminals

| Type | Name | Function | Signal standard | |

| Control power input | PV | external control power input terminal | DC24V 500mA | |

| SC | External control power OV input terminal/control signal common terminal | |||

| Control signal input | DP | NPN/PNP selection terminals | ||

| ST | Servo enabling | Optocoupler input optical PNP/NPN (optional) PNP:0V Input Validation NPN:24V Input Validation | ||

| RET | Fault resetting | |||

| I1 | Forward direction running | Programmable input | ||

| I2 | Reverse running | Programmable input | ||

| I3 | Accurate stop positioning | Programmable input | ||

| I4 | Zero speed servo | Programmable input | ||

| I5 | Inching | Programmable input | ||

| I6 | External fault input | Programmable input | ||

| I7 | Speed command1 | Programmable input | ||

| I8 | Speed command2 | Programmable input | ||

| I9 | Speed command3 | Programmable input | ||

| I10 | Speed/position control method options | Programmable input | ||

| I11 | High-speed pulse input | Programmable input | 24V,200KHz | |

| I12 | High-speed pulse input | Programmable input | ||

| Motor thermal protection | T1 | Motor thermal protection signal input | Normally open, normally closed optical | |

| Programmable output | Q1 ~ Q6 | Programmable output | Optocoupler output 24V ≤ 10mA | |

| Relay output | M0A-M0B-M0C | Driver ready to output | AC250V 1A DC30 1A | |

| M1A-M1B-M1C | Driver fault output | |||

| Analog input | FS | Internal speed setting power supply | DC10V 50mA | |

| FC | Analog common terminal | 0V | ||

| FV | Bipolar analog input | -10 ~ 10V | ||

| FI | Single polarity analog input | 0 ~ 10V/4 ~ 20mA | ||

| Analog output | DA1 DA2 | Analog output | -10 ~ 10V | |

| Encoder/pulse input | PV2/G2 | Encoder power | DC5V 100mA | |

| SA+ SA- | Pulse/encoder A phase input |

Linear drive receiving RS422 standard |

||

| PB+ PB- | Pulse/encoder B phase input | |||

| DZ+ DZ- | Pulse/encoder C phase input | |||

|

Encoder output |

OA+ OA- | encoder A phase output | Linear drive output RS422 standard | |

| OB+ OB- | encoder B phase output | |||

| OZ+ OZ- | encoder Z phase output | |||

| Motor encoder input | PV1 G1 | Provide terminal for encoder power | DC5V 100mA | |

| A+ A- | encoder A phase input | Linear drive receiving RS422 standard | ||

| B+ B- | encoder B phase input | |||

| Z+ Z- | encoder Z phase input | |||

| U+ U- | encoder U phase input | |||

| V+ V- | encoder V phase input | |||

| W+ W- | encoder W phase input | |||

| RS232 communication | T0 | RS232 communication | RS232 standard | |

| RS485 communication | D+ D- | RS485 communication | RS485 standard | |

| CAN communication | CANH CANL | CAN communication | CAN | |

| High-speed bus interface | TI | Powerlink Ethercat Mechatrolink BUS communication | Standard internet | |

| Ground terminal | E | Shield layer of signal line shall be grounded | ||

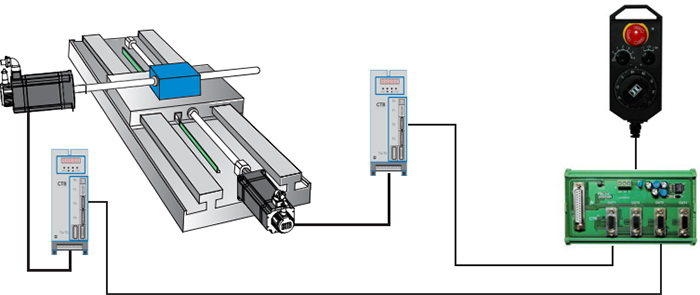

◆ Shaft fixed position system

GH ac servo drive can be widely used in coordinate axis control of CNC milling machine, lathe, gantry machine tools, which can realize:

◆Coordinate axis back to zero automatically

◆Independent handwheel control of coordinate axis

◆Can connect with various cnc system or PLC system interface via pulse interface, analog interface, bus interface.

◆Absolutely independent drive with manual single shaft

◆Programmable automatic control and auxiliary control of machine tool

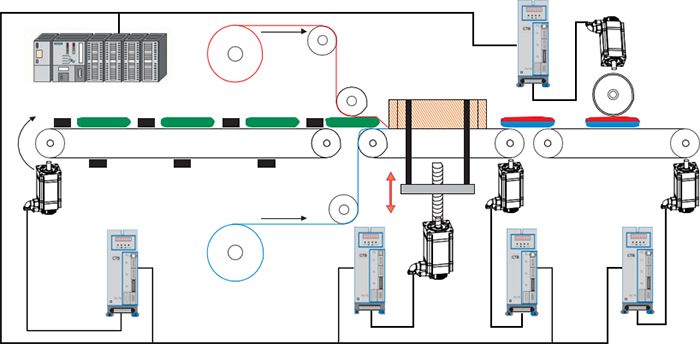

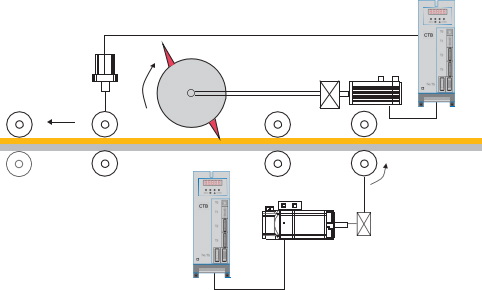

◆ Production line transmission and positioning system

Precise position control, torque control and network functions of GH ac servo drive can be fully used in:

◆Packing device and packing production line

◆ Assembling production line such as Car. home appliance etc.

◆Material transfer production line

◆ Filling production line

◆ Shearing production line

Widely applied in:

Widely applied in:

◆Cross-cutting machine, shearing plate machine

◆Wire shearing, bending equipment

◆Rolling shear production line

◆High speed flying shear (synchronous tracking shear)

length detection of encoder signal

Use external encoder interface of GH AC servo driver, can inspect the

position or length of controlled machine accurately, which can achieve fixed length, positioning control, fulfill various shearing functions:

◆Provide standard external encoder interface, Zero detecting interface

◆Built-in multiple shear control program

◆Provide man-machine interface, built-in PLC unit, maximally simplify control system

◆Suitable for various section bar, wire rod, plate material shearing equipment

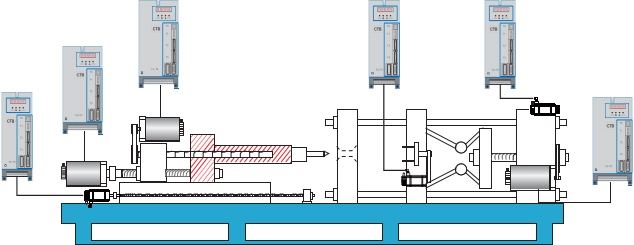

◆ All electric injection molding machine applying solutions

◆ All electric injection molding machine applying solutions

Adopt GH AC servo driver to drive CTB servo motor or water-cooling motor though bus connected computer, which can provide a complete set of servo control solution for all electric injection molding machine and achieve:

◆Movable mould fast moving, mould clamping of big torque

◆Coordinated control of glue-smelting motor and plastic injection motor makes backpressure of melt glue adjust flexibly, improve the quality of melt and efficiency

◆Closed loop of plastic injection pressure sensor and motor accomplishes accurate control of pressure, speed, injection volume

◆Make the motion fulfill more accurate, easy for adjustment regarding servo control of thimble, moulding-adjustment, injection

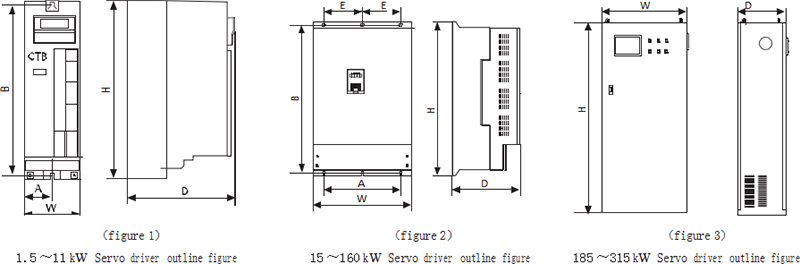

◆ Outline and mounting size

| Size Model | A | B | W | H | D | E | Terminal srew | Mounting srew | Weight(kg) | Remark |

| BKSC-41P5GH | 45.5 | 276 | 91 | 290 | 200 | – | Line card width 3mm | M6 | 3 | (figure1) |

| BKSC-42P2GH | ||||||||||

| BKSC-43P7GH | ||||||||||

| BKSC-45P5GH | 80 | 276 | 132 | 290 | 200 | – | Line card width 5mm | M6 | 5 | |

| BKSC-47P5GH | ||||||||||

| BKSC-4011GH | ||||||||||

| BKSC-4015GH | 140 | 380 | 194 | 400 | 230 | – | M6 | M6 | 14 | (figure2) |

| BKSC-4018GH | ||||||||||

| BKSC-4022GH | 236 | 376 | 282 | 390 | 270 | – | M6 | M8 | 20 | |

| BKSC-4030GH | ||||||||||

| BKSC-4037GH | 300 | 376 | 380 | 390 | 270 | – | M8 | M8 | 26 | |

| BKSC-4045GH | ||||||||||

| BKSC-4055GH | 392 | 376 | 472 | 390 | 270 | 196 | M10 | M8 | 33 | |

| BKSC-4075GH | ||||||||||

| BKSC-4090GH | 360 | 690 | 464 | 720 | 320 | 180 | M10 | M16 | 90 | |

| BKSC-4110GH | ||||||||||

| BKSC-4132GH | ||||||||||

| BKSC-4160GH | ||||||||||

| BKSC-4185GH | – | – | 800 | 1800 | 450 | – | – | – | 230 | (figure3) |

| BKSC-4220GH | ||||||||||

| BKSC-4315GH |