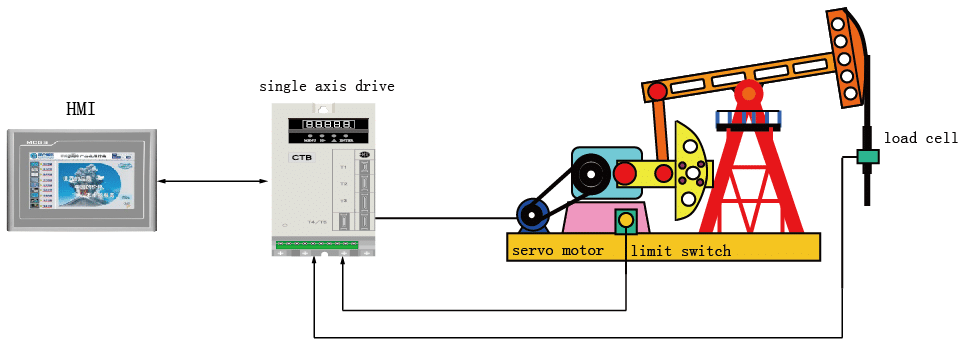

Configuration scheme

Man-machine interface + single shaft drive+ servo motor +load sensor + limit switch

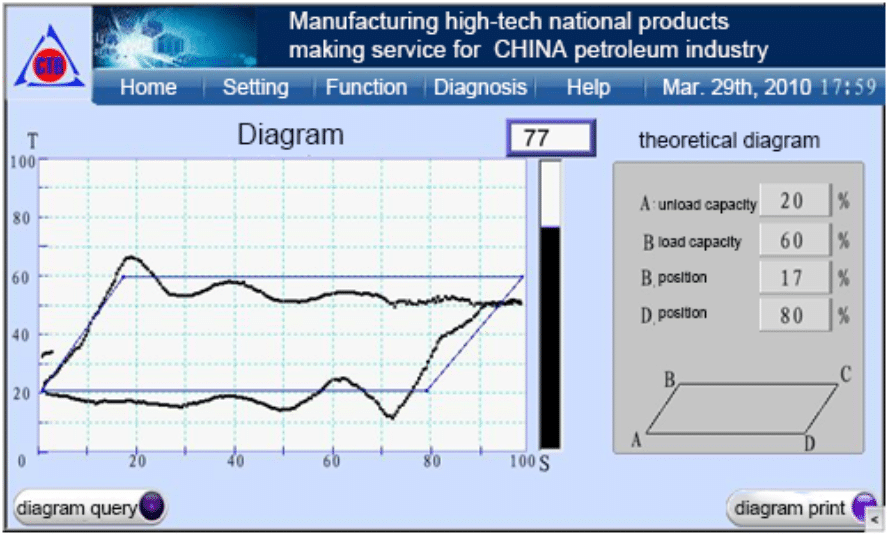

Test indicator diagrams

Intelligent CPU of servo control system, adopting the optimization of the energy saving control software, timely detect load change in each stroke of sucker rod (or motor), according to the load change, form the indicator diagrams, then according to the indicator diagrams situation, adjust the motor speed, change pumping rate, automatically find the best pumping rate after constant adjustment.

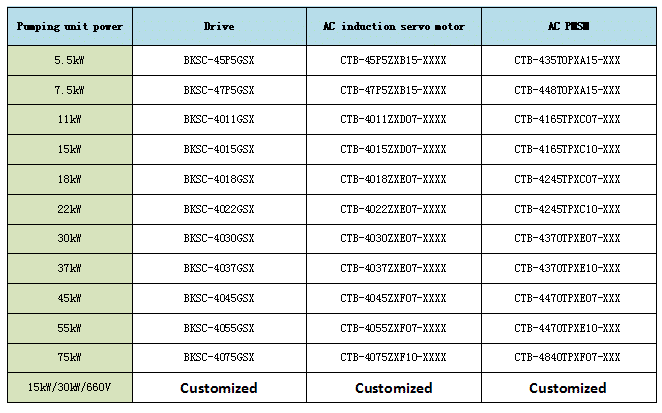

Selection reference

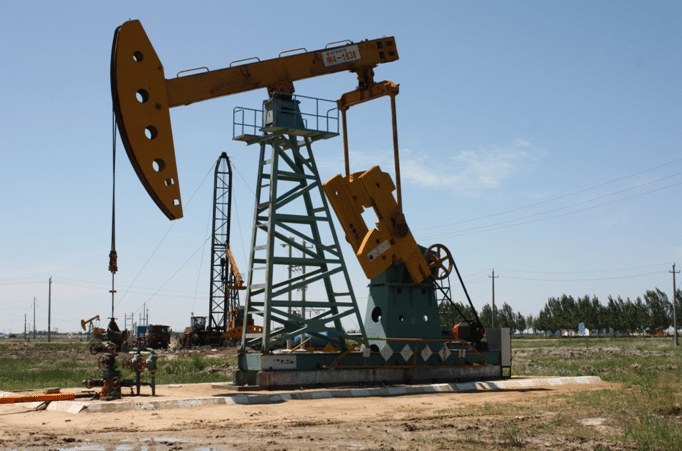

CASE

● User:Da qing oilfield(three factory, five, six, ten factory)

● Pumping unit:Beam pumping unit, screw pump

● Power:15~75kW/380V、15kW/660V、30kW/660V

● Motor:AC induction motor、Customized 660V medium voltage ac induction motors

● Drive:GS series、Customized medium voltage drive

● Production equipment pictures as below

.

Some other users

Liao he oilfield

Sheng li oil field

Fu yang zhong yuan oilfield

Ji dong oilfield