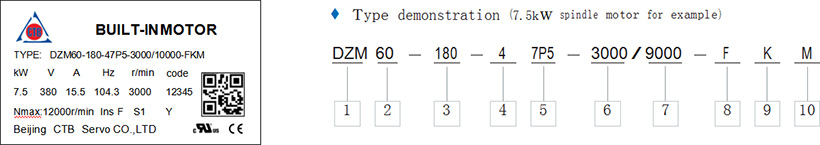

◆ Type demonstration

| Model | Name | Description | Catalog No. Explanation |

| 1 | Motor type code | DZM:built-in induction spindle motor | built-in induction spindle motor |

| 2 | Series code | 46 60 74 85 100 110 124 146 160 170 195 215 | 60 series |

| 3 | Core length | Unit:mm | Core length: 180mm |

| 4 | Voltage class | 2:200V 4:400V | 400V class |

| 5 | Power code | See standard specification table | 7.5kW |

| 6 | Rated speed | Unit:rpm | Rated speed:3000 rpm |

| 7 | Constant power max speed |

Unit:rpm | Constant power max speed:9000 rpm |

| 8 | Cooling method code | Code cooling method Code cooling method F: air cooling L: liquid cooling |

air cooling |

| 9 | Rotor installation method | Code Installation method Code Installation method N: direct thermal sleeve K: through-hole mounting Z: expanding-hub mounting J: Key mounting | Through-hole mounting |

| 10 | Stator structure type | Code structure method M:blank stator (stator excircle unprocessed, stator end not grout glue) G:glue stator(stator excircle finishing, end grout glue) T:with cooling jacket(stator with external cooling jacket, end grout glue) |

Blank stator |

| Remark | ▲ Insulation class F ▲ stator built-in KTY84 temperature sensor and 130℃ normal close thermal protection ▲ Stator lead wire JYJ-150(0.5m) |

||

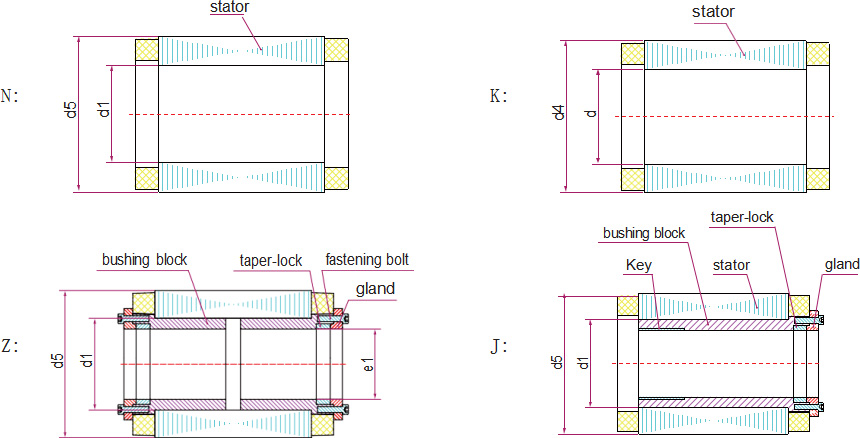

◆ Stator mounting method figure

Standard series

◆ Shape size figure

◆ DZM series Rotor shape size Note:”()” means blank dimension

| Motor model | Rotor shape size | ||||||||||

| a | d | (d1) | d2 | d3 | d4 | (d5) | e1 | e2 | L2 | L | |

| DZM46 | 15 | 46 | 45 | 53 | 69 | 70.4 | 71 | 40 | 45 | 10 | see standard specification table |

| DZM60 | 25 | 60 | 58.5 | 68 | 95 | 97.4 | 98 | 50 | 57 | 12 | |

| DZM74 | 28 | 74 | 72.5 | 87 | 112 | 114.3 | 115 | 65 | 73 | 14 | |

| DZM85 | 20 | 85 | 82.5 | 96 | 139.5 | 141.3 | 142 | 75 | 84 | 16 | |

| DZM100 | 30 | 100 | 98.5 | 110 | 155 | 159.2 | 160 | 75 | 84 | 16 | |

| DZM110 | 17 | 110 | 108.5 | 120 | 173 | 173.2 | 174 | 75 | 84 | 16 | |

| DZM124 | 29 | 124 | 122.5 | 135 | 196 | 199.2 | 200 | 90 | 101 | 19 | |

| DZM146 | 19 | 146 | 144 | 160 | 204 | 209.2 | 210 | 110 | 124 | 23 | |

| DZM160 | 22 | 160 | 158 | 175 | 234 | 236.1 | 237 | 125 | 139 | 23 | |

| DZM170 | 23 | 170 | 168 | 185 | 261.5 | 264 | 265 | 130 | 148 | 30 | |

| DZM195 | 27 | 195 | 192 | 210 | 289.5 | 292.8 | 294 | 160 | 178 | 30 | |

| DZM215 | 25 | 215 | 212 | 245 | 379 | 383.6 | 385 | 160 | 178 | 30 | |

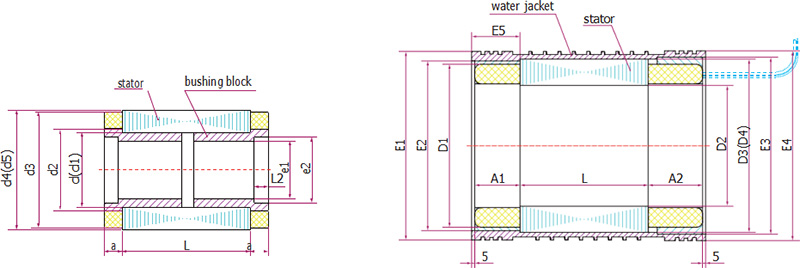

◆ DZM series Rotor shape size Note:”()” means blank dimension

|

Motor model |

Rotor shape size | |||||||||||

| A1 | A2 | D1 | D2 | D3 | (D4) | E1 | E2 | E3 | E4 | E5 | L | |

| DZM46 | 40 | 45 | 110 | 71 | 120 | 121 | 132 | 118 | 121 | 132 | 45 | see standard specification table |

| DZM60 | 45 | 50 | 142 | 98 | 156 | 157 | 166 | 154 | 157 | 167 | 50 | |

| DZM74 | 45 | 55 | 165 | 115 | 180 | 181 | 197 | 179 | 182 | 200 | 50 | |

| DZM85 | 55 | 60 | 195 | 142 | 210 | 211 | 228 | 200 | 212 | 230 | 57 | |

| DZM100 | 60 | 65 | 230 | 160 | 250 | 251 | 268 | 245 | 251 | 270 | 60 | |

| DZM110 | 65 | 70 | 235 | 174 | 255 | 256 | 284 | 245 | 257 | 286 | 60 | |

| DZM124 | 75 | 85 | 270 | 200 | 292 | 293 | 312 | 285 | 293 | 314 | 75 | |

| DZM146 | 70 | 75 | 275 | 210 | 300 | 301 | 328 | 290 | 302 | 330 | 62 | |

| DZM160 | 65 | 75 | 305 | 237 | 330 | 331 | 358 | 320 | 332 | 360 | 65 | |

| DZM170 | 75 | 85 | 345 | 265 | 370 | 371 | 398 | 360 | 372 | 400 | 70 | |

| DZM195 | 80 | 90 | 370 | 294 | 400 | 402 | 428 | 390 | 402 | 430 | 73 | |

| DZM215 | 95 | 105 | 490 | 385 | 520 | 522 | 548 | 512 | 523 | 550 | 85 | |

◆ DZM60 series built-in motor standard specification

Voltage grade:400V Pole:4 Limit speed:18000rpm

|

Core length L |

basic speed (rpm) | air cooling | liquid cooling | ||||||||

| model DZM60- | Power (kW) | Torque (N.m) | Current (A) | Max speed | model DZM60- | Power (kW) | Torque (N.m) | Current (A) | Max speed | ||

| 70 | 1500 | 70-41P5-1500/ 4500-FXX | 1.5 | 9.5 | 3.5 | 6000 | 70-42P2-1500/2500-LXX | 2.2 | 14.0 | 5.2 | 4500 |

| 70 | 3000 | 70-43P7-3000/ 7500-FXX | 3.7 | 12.0 | 7.8 | 9000 | 70-45P5-3000/5500-LXX | 5.5 | 17.5 | 12.0 | 8000 |

| 120 | 1500 | 120-43P0-1500/ 4000-FXX | 3.0 | 19.0 | 6.7 | 6000 | 120-43P7-1500/3000-LXX | 3.7 | 23.6 | 8.2 | 4500 |

| 120 | 2000 | 120-43P7-2000/ 6000-FXX | 3.7 | 18.0 | 8.0 | 8000 | 120-45P5-2000/4000-LXX | 5.5 | 26.0 | 12.0 | 6000 |

| 120 | 3000 | 120-45P5-3000/ 9000-FXX | 5.5 | 17.5 | 11.5 | 10000 | 120-47P5-3000/6500-LXX | 7.5 | 24.0 | 15.5 | 8000 |

| 180 | 1500 | 180-44P0-1500/ 4500-FXX | 4.0 | 25.5 | 8.6 | 6000 | 180-45P5-1500/3000-LXX | 5.5 | 35.0 | 12.0 | 4500 |

| 180 | 2000 | 180-45P5-2000/ 6500-FXX | 5.5 | 26.0 | 12.0 | 8000 | 180-47P5-2000/4500-LXX | 7.5 | 35.8 | 16.0 | 6000 |

| 180 | 3000 | 180-47P5-3000/10000-FXX | 7.5 | 24.0 | 15.5 | 12000 | 180-4011-3000/7500-LXX | 11.0 | 35.0 | 23.0 | 8000 |

| 240 | 1500 | 240-45P5-1500/ 5000-FXX | 5.5 | 35.0 | 12.0 | 6000 | 240-47P5-1500/3500-LXX | 7.5 | 48.0 | 16.0 | 6000 |

| 240 | 3000 | 240-4011-3000/10000-FXX | 11.0 | 35.0 | 23.0 | 12000 | 240-4015-3000/7500-LXX | 15.0 | 48.0 | 30.0 | 9000 |

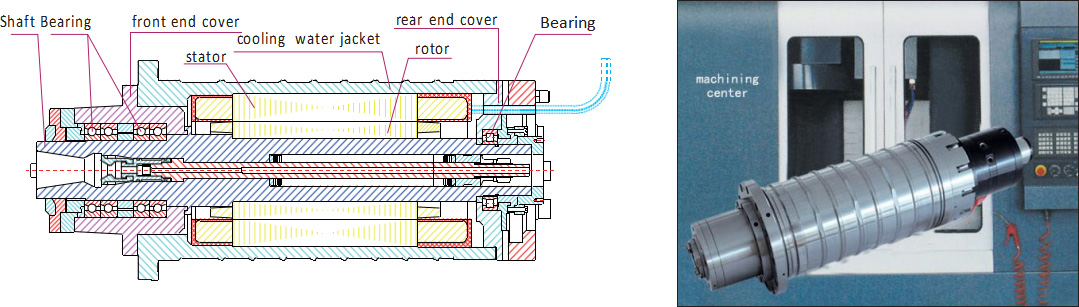

Design scheme

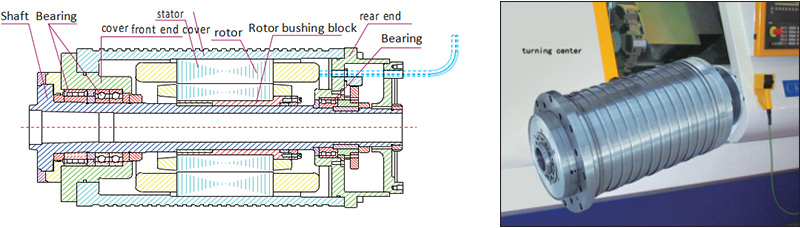

◆ Motorized spindle of machining center

Applying area: CNC milling machine machining center CNC boring machine Suitable tool holder:BT(CT)series、Morse series、ISO series、BIN series、ER series

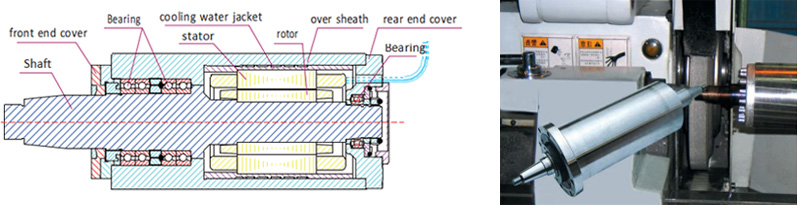

◆ NC lathe motorized spindle

Applying area:Meter lathe, Gang Tool Type Lathe, CNC lathe( horizontal lathe bed, slant bed)

◆ Grinder motorized spindle

Applying area:Internal grinder, cylindrical grinder, surface grinder